Key Investment Casting Technical Parameters

Linear Tolerance

Dimensions (mm) |

Normal (mm) |

The Equivalent |

Premium (mm) |

The Equivalent |

||

ISO8062-3 (2007) |

VDG P690 (1990) |

ISO8062-3 (2007) |

VDG P690 (1990) |

|||

0-10 |

±0.26 |

DCTG6 |

D2 |

±0.13 |

DCTG4 |

D3 |

10-16 |

±0.27 |

DCTG6 |

D1 |

±0.14 |

DCTG4 |

D2 |

16-25 |

±0.28 |

DCTG6 |

D1 |

±0.15 |

DCTG4 |

D2 |

25-40 |

±0.32 |

DCTG6 |

D2 |

±0.23 |

DCTG5 |

D2 |

40-63 |

±0.35 |

DCTG6 |

D2 |

±0.25 |

DCTG5 |

D2 |

63-100 |

±0.55 |

DCTG7 |

D1 |

±0.39 |

DCTG6 |

D2 |

100-160 |

±0.90 |

DCTG8 |

D1 |

±0.60 |

DCTG7 |

D2 |

160-250 |

±1.40 |

DCTG9 |

D1 |

±1.00 |

DCTG8 |

D2 |

250-400 |

±2.20 |

DCTG10 |

D1 |

±1.60 |

DCTG9 |

D2 |

>400 |

±.8% |

DCTG11 |

D1 |

±0.5% |

DCTG9 |

D2 |

Size And Weight Range

Items |

Size |

Premium |

Outline Dimension (mm) |

1000×620×380 |

﹤100 |

Weight (Kg) |

0.001-80 |

0.1-1.5 |

Min.Wall Thickness (mm) |

0.5 |

5-10 |

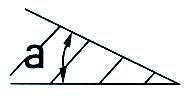

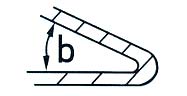

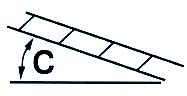

Angle Tolerance

Angle Type |

|

|

|

Normal |

±1° |

±2° |

±2° |

Premium |

±0.5° |

±1° |

±1° |

Avoid the quick changes of casting structure,use fillet radius on |

|

||

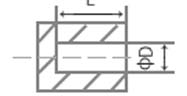

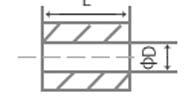

Limit Dimension For Cast Holes and Slots

Items |

Hole Dia.(mm) |

L/D |

|

Φ2-Φ3 |

L/D≤2 |

Φ4-Φ7 |

L/D≤5 |

|

≥Φ8 |

L/D≤10 |

|

|

Φ2-Φ3 |

L/D≤1 |

Φ4-Φ7 |

L/D≤2.5 |

|

≥Φ8 |

L/D≤3.5 |

|

Deeper and more complicated holes and slots can be casted by using soluble wax cores and ceramic cores. |

||

Tolerance for Flatness, Straitness and Roundness

Dimension (mm) |

Normal |

Premium |

0-25 |

0.2 |

0.1 |

25-50 |

0.4 |

0.2 |

50-100 |

0.6 |

0.3 |

100-150 |

0.8 |

0.4 |

Surface Roughness

Rough Castings |

(Weight) >5kg Main Wall Thickness >12 mm |

Ra3.2-6.3 |

(Weight) <5kg Main Wall Thickness <12 mm |

Ra1.6-3.2 |

|

Finished Castings |

0.8-1.6 |

|