FLOWTECH CHINA 2025 Shanghai Pump&Valve Exhibition And Kelin’s Exhibition

Release Time:2025-10-07

Dongying Kelin’s Exhibition In FLOWTECH CHINA 2025 Shanghai Pump&Valve Exhibition

FLOWTECH CHINA 2025 Shanghai Pump&Valve Exhibition came to a close on 6th June,2025 in Shanghai National Exhibition&Convention Center(Hongqiao). As the largest national pump&valve exhibition, Flowtech China 2025 gathers distinguished global&domestic pump&valve brands, Technology Solution Providers& Pump&Valve Parts Manufacturers each year. The below are some of the exhibitors disclosed by the Exhibition Organizer.

|

|

Apart from Pump&Valve Brands, one of the highlights is the category of OEM manufacturers for pump&valve custom parts. Particularly highlighted are the exhibitors that manufacture pump&valve custom castings by silica sol lost wax investment castings. At least, 10 silica sol lost wax investment casting foundries exhibited in the pump section of the exhibition alone (Including Dongying Kelin Precision Machinery Co.,ltd). In terms of expanding their castings supply chain and implementing pump&valve OEM custom cast parts, pump&valve brands and professional casting buyers benefited from the presence of the investment casting exhibitors in this exhibition.

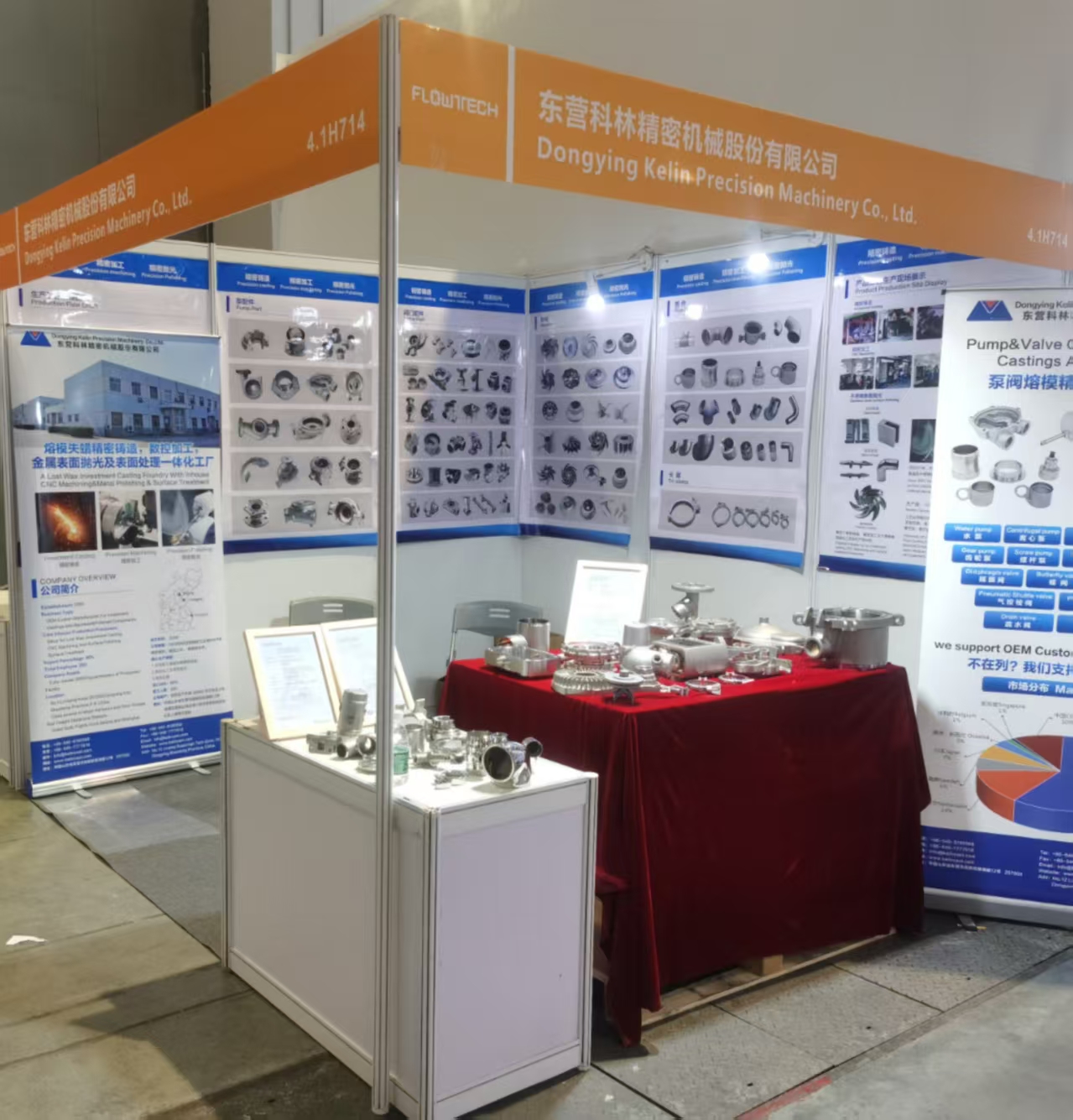

As an pump&valve OEM investment casting manufacturer for domestic and overseas market pump&valve brands, Dongying Kelin Precision Machinery exhibited in hall 4.1 pump sector for 3 days. Our exhibition stand and samples received high visitor traffic and attention.

|

|

|

Kelin’s Exhibition Stand&Investment casting Samples For Pump&Valve Application

|

|

|

Kelin’s Exhibition Stand&Investment casting Samples For Pump&Valve Application

We exchanged contacts and had in-depth communication on investment casting demands with businesses from Chemical Pump,water pump, gear pump, butterly valve, hydraulic engineering ,energy and other flow control sectors. Shortly after the exhibition, we received inquiries and accomplished visits invited by prospective customers from this exhibition. Having learned the quality issues of their castings, We proposed our investment casting production solution in regard to their investment casting demand. Upon attempting tooling and sampling, we have reached the batch production stage with some customers from the exhibition. Apart from creating new toolings, we also collaborated with customers who would like us to use their current toolings, thus minimizing development costs.

Advantages of Silica Sol lost-wax Investment Casting in Manufacturing Pump&Valve Components.

The Investment casting process is applied extensively in the manufacturing of components of many pum&valves, such as closed impellers, open impellers, pump casing, valve body, valve plates , flanges, pump cover etc.

The process conduces to but not limited to the followings of pump&valve components manufacturing:

- Higher and More Stable Dimension &Tolerance Accuracy For Assembly

In comparison to other casting processes, silica sol lost wax investment casting delivers higher and consistent linear dimension and geometrical tolerance accuracy. Thus, it delivers benefits such as higher assembly precision, better runner precision for flow control, higher sealing against leakage, higher structural strength resulting from less dimensional deviation&less local stress. Taking examples of casting linear tolerance, tolerance of castings made from silica sol lost wax investment casting can be executed at DCTG4-6 levels.

- Fine Surface Finish

The silica sol lost wax investment casting process delivers a surface roughness of Ra 3.2-Ra 6.3. A better surface Finish can be realized under further surface treatment like vibration grinding, electro-polishing& mirror polishing. The fine surface finish offers more reliability and compatibility with different varieties of fluid media such as food, medicine, beverages, chemical substances.

- Complex Geometrical Design.

The silica sol lost wax investment casting process is applicable for manufacturing parts of complex geometries.Unlike the demolding of sand casting, the investment casting shell is a shaped and calcinated ceramic container where melted metal was poured into. After the investment casting shell cools, it can be removed from the casting by mechanical deshelling easily. Investment cast shell remains in Deep holes and intricate inner contours (eg: closed impellers )can also be removed by chemical process such as soda boiling.By delicate wax injection tooling design, we can deploy water soluble core or ceramic core to realize wax parts of complex structures such as the vortex structure of pump case and the deep and narrow runners of closed impellers.

Batch Production Flexibility& Economical Near-net Production

A wax part injection tool and other jigs are pre-investment assets of customers, thus the silica sol lost wax investment casting process is inherently suitable for medium to large batch production. However, Dongying Kelin Precision Machinery is capable of handling Multiple varieties in small batches as a result of our equipments, HR&production organizing capability& our extensive range of products and materials. The process offers a near-net and economical production. When machining&welding are necessary, the high dimension accuracy&fine surface finish lessens the demand for machining&welding moderately in comparison to other casting method.

Since our establishment in 2004, Dongying Kelin Precision Machinery Co.,Ltd has manufactured investment castings for the pump&valve&process control industries. We offer one stop solution that incorporates feasibility check, joint development, tooling design, investment casting, machining, polishing &assembly &surface treatments.

|

Dongying Kelin Machinery Co.,ltd is a lost-wax investment casting foundry with inhouse machining and stainless steel surface polishing. Established in 2004, Kelin, with his highly-adaptable processes, has served the investment casting demand of different market sectors internationally and domestically. For more information of our processes, please contact info@kelincast.com

Precision Casting, Precision Machining, Precision Polishing No.12,Linqing Road,Shengli Industrial Zone, 257081,Dongying,Shandong Province, China E-mail:info@kelincast.com Web:www.kelincast.com D: +86 (546) 7777668 | FAX: +86 (546) 7777618 |

DongYing KeLin Precision Machinery Co.,Ltd.

DongYing KeLin Precision Machinery Co.,Ltd.